- Summary

- Parameters

- Size chart

- Model order

- Download

- Communication

Intelligent Gas Precession Vortex Flowmeter

Overview

Intelligent gas precession vortex flowmeter is a new type of gas flow meter which developed by our company with advanced technology. It has the function of measuring flow, temperature, and pressure; it also can compensate temperature, pressure and compressible factor automatically. It is an ideal instrument of gas measurement which is used for petroleum, chemical industrial, electricity, metallurgy, and so on.

Features

1. Has no mechanical moving parts, difficult to be corroded, steady and reliable, with long operating life, can work for a long time without special maintenance;

2. Adopts 16 bits computer chip, with high integration level, small volume, excellent property, and great function of complete instrument;

3. Intelligent flowmeter integrates flow probe, microprocessor, pressure and temperature sensor, selects in-built combination for more compact structure, can measure fluid’s flow, pressure and temperature directly, and realizes real-time tracking and compensation, as well as correcting compressible factor;

4. Adopts double detecting technique to improve the strength of detection signal effectively and suppress the interference from pipeline’s vibration;

5. Adopts national leading vibration-proof technique, which can suppress interference signal caused by vibration and pressure fluctuation;

6. Adopts English dot matrix display which displays more digitals, read intuitively and conveniently, can display parameters directly such as volume flow rate under working state and standard state, volume dose, mediem pressure , temperature, and so on;

7. Adopts EEPROM technique, parameters can be set conveniently and preserved permanently, the time of preserving history date can reach up to one year;

8. Converter can output frequency pulse, 4~20mA analog signal, and has RS485 interface, it can build a network with microcomputer directly, the transmission distance can reach 1.2km;

9. Outputs warning with various physical parameters, users can choose any one from them;

10. Flowmeter head can rotate 360 degree, can be installed and used easily and conveniently;

11. Coordinates with our company’s FM date acquisition unit, can transmit remote date through internet or telephone network;

12. Pressure and temperature signals are input by sensor, with high interchangeability;

13. Overall power dissipation is low, can be powered by internal battery or external power source;

14. With multiple materials that can measure special gas, such as red copper for chlorine.

Operating Principle

Flow transmitter’s profile is similar to venturi’s molded line (see in picture). Place a group of spiral guide vanes in the inlet side, when fluid enter in the flow transmitter; the guide vanes force the fluidcausing drastic spiral flow. When the fluid enters in the diffuse part, the spiral flow starts second rotating and forms gyro-type vortex propulsion phenomenon because of flow-back effect. The precession frequency is proportional to the flow volume, and it isn’t affected by fluid’s physical property and density. Detecting element can get good linearity in quite side flow range after measuring the second vortex procession frequency of the fluid. Signal is magnified, filtered, shaped by amplifier, then it is converted to pulse signal which is proportional to the flow rate. Then the pulse signal is sent to microprocessor for flow totalizing, and the LCD will display the measured result (instantaneous flow, cumulative flow, and temperature and pressure data).

Main Technical Parameters

|

Nominal Diameter DN(mm) |

Range of Flow |

Working Pressure(MPa) |

Accuracy |

Repeatability |

|

15 |

1.5~12 |

1.6 2.5 4.0 6.3 10 16 25 42 |

1.0 1.5 |

Smaller than 1/3 absolute value of basic error limit |

|

20 |

2~15 |

|||

|

25 |

3.0~30 |

|||

|

32 |

6.0~60 |

|||

|

40 |

7.0~70 |

|||

|

50 |

10~130 |

|||

|

80 |

30~400 |

|||

|

100 |

70~800 |

|||

|

125 |

90~1000 |

|||

|

150 |

190~1900 |

|||

|

200 |

240~3600 |

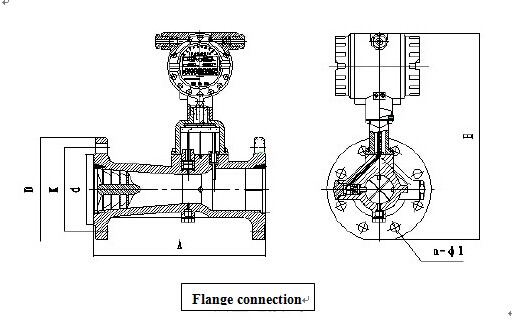

Installing Boundary and Dimension

| Nominal Diameter |

15 |

25 |

40 |

50 |

80 |

100 |

150 |

200 |

250 |

300 |

|

L(mm) |

300 |

300 |

350 |

350 |

450 |

450 |

500 |

600 |

600 |

650 |

|

H(mm) |

300 |

300 |

300 |

300 |

350 |

380 |

400 |

450 |

500 |

550 |

Ordering Model

|

Nominal Diameter DN(mm) |

Nominal Pressure (MPa) |

Dimension (mm) |

Material of Meter |

Weight (kg) |

Connection |

||

|

Length of meter A |

Height H |

Stainless steel |

Aluminum alloy |

|

Flange Thread Clamp |

||

|

15/20 |

1.6、2.5、4.0 |

160 |

360 |

Stainless steel |

Aluminum alloy |

6 |

|

|

6.3、10 |

160 |

365 |

Stainless steel |

|

8 |

||

|

25 |

1.6、2.5、4.0 |

180 |

367 |

Stainless steel |

Aluminum alloy |

7 |

|

|

6.3、10 |

180 |

378 |

Stainless steel |

|

10 |

||

|

32 |

1.6、2.5、4.0 |

200 |

383 |

Stainless steel |

Aluminum alloy |

9 |

|

|

6.3、10 |

200 |

402 |

Stainless steel |

|

12 |

||

|

40 |

1.6、2.5、4.0 |

200 |

383 |

Stainless steel |

Aluminum alloy |

9 |

|

|

6.3、10 |

200 |

402 |

Stainless steel |

|

12 |

||

|

50 |

1.6、2.5、4.0 |

230 |

403 |

Stainless steel |

Aluminum alloy |

11 |

|

|

6.3、10 |

230 |

421 |

Stainless steel |

|

14 |

||

|

80 |

1.6 |

330 |

438 |

Stainless steel |

Aluminum alloy |

11 |

|

|

2.5、4.0 |

330 |

438 |

Stainless steel |

|

18 |

||

|

6.3、10 |

330 |

446 |

Stainless steel |

|

21 |

||

|

100 |

1.6 |

410 |

468 |

Stainless steel |

Aluminum alloy |

14 |

|

|

2.5、4.0 |

410 |

475 |

Stainless steel |

|

18 |

||

|

6.3、10 |

410 |

483 |

Stainless steel |

|

33 |

||

|

150 |

10 |

585 |

542 |

Stainless steel |

Aluminum alloy |

21 |

Flange |

|

1.6、2.5 |

585 |

549 |

Stainless steel |

|

52 |

||

|

4.0、6.3、10 |

585 |

572 |

Stainless steel |

|

72 |

||

|

200 |

1.0 |

700 |

618 |

Stainless steel |

Aluminum alloy |

41 |

|

|

1.6、2.5 |

700 |

626 |

Stainless steel |

|

117 |

||

|

4.0、6.3、10 |

700 |

634 |

Stainless steel |

|

127 |

||