FirstCon Oil and Gas Production IoT Systems (Internet of things)

I. System Introduction

FirstCon Oil and Gas Production IoT (Internet of things) System (referred to as: FC_IProd), including acquisition and control, data

transmission, working conditions analysis and forecasting, IoT network and equipment management, production operating management and so on, in total, there are five subsystems. The system is through a combination of sensing technology, RF, communications, advanced computing technology ,to finish the comprehensive sensing of oil and gas wells, metering room, gas stations and other production object. It achieves the central management and control of the production data, device situation in the production command center and control center. It builds up the specifications, unified data management platform to support oil and gas production process management, provide real-time analysis and optimization of oil and gas production, and further enhance the timeliness and accuracy of oil and gas production decisions, in order to achieve the purpose of saving oil and gas production construction investment and operating costs.

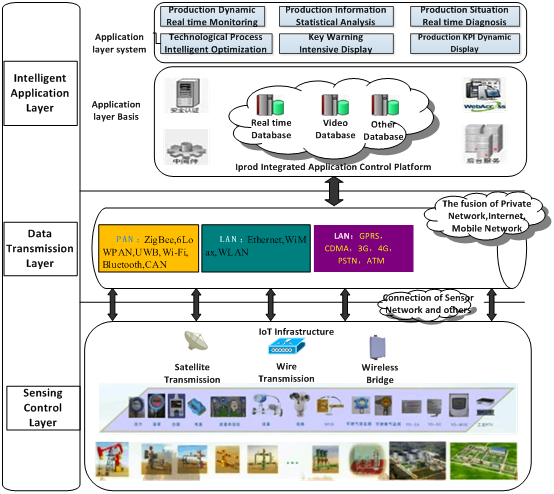

The system uses three-tier framework of IoT(Internet of Things), by the sensing layer, transport layer and application layer. The sensing layer achieves the real- time acquisition(sensors, cameras) of the information node in production systems, such as wellheads,underground, pipelines, depots. The transport layer using the bridge, GPRS / CDMA and other wireless mode transmit the data to command center. The application layer achieves the real-time monitoring, production trend forecasting and multi-layered intelligence applications in the whole-process of oil and gas production.

FirstCon Oil and Gas Production IoT System

III.System Function

■ Provide Intelligent Application

■ Real-time data ability

■ Standard hardware/Storage/ Safety Program

■ Third party system integration ability

■ System resource integration and sharing ability

■ System smooth evolution ability

IV.Service System

■ Energy-saving services: energy saving design / energy-saving projects / energy management

■ Technology support services: energy consulting / energy-saving diagnosis / management support services for

the energy-saving procedures

■ Management support service: comparison of energy consumption ranking / assessment of the energy efficiency / saving potential assessment

■ Data base services: energy consumption data reporting / preliminary data analysis / software training

■ Energy monitoring services: monitoring program design / networking integration / project implementation

![]()