- Summary

- Parameters

- Size chart

- Model order

- Download

- Communication

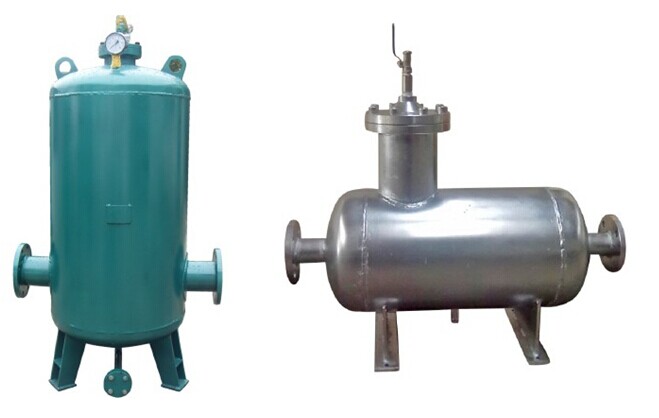

LPX Air Separator

Overview

According to structural style, LPX Air separator is divided in two types, horizontal type and vertical type. It is used to separate and exhaust the gas in measured liquid. In most instances, all measured liquid contains gas in varying degrees. If let the gas get into flowmeter, it will affect the measuring accuracy of flowmeter. So the air separator is indispensible auxiliary equipment in flow measurement system, especially in measurement system with high accuracy.

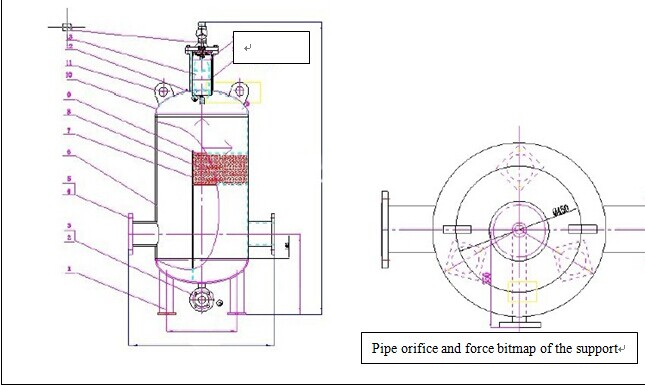

Vertical Type of Air Separator

Structure

Vertical type air separator mainly consists of shell, floating ball valve, middle tube, etc. the shell bears working pressure of measured liquid and forms the space that the air separator requires. The middle tube creates excellent condition for separating oil and gas. The floating ball valve’s main function is to exhaust gas according to leverage theory, it consists of floating ball, valve rode, valve element, valve seat and connecting rod of floating ball. The valve element and the valve seat constitute a big valve; the valve rode and the valve element constitute a small valve.

Operating Principle

When liquid flow into air separator from inlet, it hits against the cantboard under the middle tube to separate fluid and make the preliminary step of separating oil and gas, then it flows upward along the gap between middle tube and shell to complete draining oil separation. (Second time to separate oil and gas in the cavity filled with material) The liquid continue flowing upward and enter air separating head on top, when the proportion of oil and gas is very big, the floating ball pulls out the piston of air separating head under the effect of weight, and let the gas out of tank. As the gas venting and liquid lever rising, the floating ball floats up and pushes the piston, then as the liquid level and pressure increasing, the floating ball pushes exhaust vent and closes it. By this way, exhausting function can be realized. The ball valve on exhausting head is always open in normal conditions, but it closes to prevent liquid spraying out when air separator failures. Adjusting the switch of ball valve can control exhausting velocity.

Horizontal Type of Air Separator

Structure

Horizontal type air separator mainly consists of shell, floating ball valve, exhausting ball valve, oil draining plate, etc. the shell bears working pressure of measured liquid and forms the space that the air separator requires. The draining oil plate creates excellent condition for separating oil and gas. The floating ball consists of floating ball, link mechanism, valve seat and shield. The floating ball moves up and down along with the liquid level to control the switch of main valve and side valve for exhausting gas.

Operating Principle

When a fluid flows along the direction of arrow to air separator, it hits against oil draining plate first to be separated to water and gas, then it enters clapboard to be separated again, the gas of it keeps rising along clapboard until reaches the top of tank and forms the gas space. As the gas space extending and liquid level declining constantly, the floating ball gets the rod valve moving under the effect of its own weight to open the piston valve and let the gas out. As the gas venting largely, the gas-liquid interface and the floating ball rising constantly to drive the rode valve then close the piston. The air separator works in this way repeatedly to realize the function of exhausting.

Main Technical Parameters

|

Model |

Inside Nominal Diameter (mm) |

Nominal Pressure MPa |

Medium Temperature ℃ |

Medium Proportion g/ cm2 |

Medium Viscosity pa.s |

Pressure Loss MPa |

|

|

Horizontal Type |

LPX25 |

25 |

1.6

2.5

4.0

6.4 |

-20~120 |

≥0.74 |

3~500 |

≤0.07 |

|

LPX40 |

40 |

||||||

|

LPX50 |

50 |

||||||

|

LPX80 |

80 |

||||||

|

LPX100 |

100 |

||||||

|

LPX150 |

150 |

||||||

|

LPX200 |

200 |

||||||

|

LPX250 |

250 |

||||||

|

LPX300 |

300 |

||||||

|

LPX350 |

350 |

||||||

|

LPX400 |

400 |

||||||

|

Vertical Type |

LPX500 |

500 |

|||||

Dimension Figure

|

Model |

Inside Nominal Diameter (mm) |

Connecting Length L |

Installation Height H |

Height H1 |

|

|

Horizontal Type |

LPX25 |

25 |

745 |

285 |

690 |

|

LPX40 |

40 |

896 |

326 |

734 |

|

|

LPX50 |

50 |

1320 |

326 |

734 |

|

|

LPX80 |

80 |

1320 |

378 |

836 |

|

|

LPX100 |

100 |

1620 |

378 |

836 |

|

|

LPX150 |

150 |

1620 |

428 |

936 |

|

|

LPX200 |

200 |

2350 |

428 |

936 |

|

|

LPX250 |

250 |

2350 |

588 |

1195 |

|

|

LPX300 |

300 |

3010 |

588 |

1195 |

|

|

LPX350 |

350 |

3010 |

750 |

1455 |

|

|

LPX400 |

400 |

900(600) |

750 |

1455 |

|

|

Vertical Type |

LPX80 |

80 |

900(700) |

600(500) |

1815(1000) |

|

LPX100 |

100 |

1100(800) |

600(500) |

1815(1200) |

|

|

LPX150 |

150 |

1325(1000) |

700(600) |

2100(1500) |

|

|

LPX200 |

200 |

1325(1200) |

900(700) |

3380(1800) |

|

|

LPX250 |

250 |

1325(1200) |

900(800) |

3380(1900) |

|

|

LPX300 |

300 |

2100(1200) |

900(800) |

3380(2000) |

|

|

LPX350 |

350 |

2100(1200) |

1250(900) |

4462(2500) |

|

|

LPX400 |

400 |

2100(1500) |

1250(1000) |

4462(2500) |

|

|

LPX500 |

500 |

2100(1600) |

1250(1000) |

4462(2500) |

|