- Summary

- Parameters

- Size chart

- Model order

- Download

- Communication

Features

1. High accuracy

Because Porous Balance Flow Sensor is actually a flow rectifier, can effectively have no swirl and improve the velocity distribution distortion, make the flow field approximate to ideal state, the conventional measurement is grade 0.5, high-precision measurement is grade 0.2.

2. Wide turndown ratio

Because large-caliber and small-flow measurement is the problem that most of the flow sensors have, and Porous Balance Flow Sensor is a porous structure, to select the appropriate equivalent diameter ratio can pay a major emphasis on the measurement of lower limit and also give consideration to the upper flow, making flow turndown ratio of routine measurement is 10 : 1. If you choose the appropriate parameters, it can be increased to 300: 1-500: 1.

3. Low requirements of straight pipe

Certain length of straight pipe is mainly used in which the fluid tends to be stabilized when flowing, while Porous Balance Flow Sensor itself is a flow regulator, so it almost can be connected directly to the valve, tee joint , elbow baffles and does not affect the normal measurement

4. Low permanent pressure loss

Flow sensors are installed on the pipe, due to the flow resistance function, it’s inevitable to generate a pressure loss, and the porous structure of the flow sensor can disperse resistance, effectively reduce the formation of vortex and friction of the turbulence, thereby to reduce the permanent pressure loss.

Operating Principle

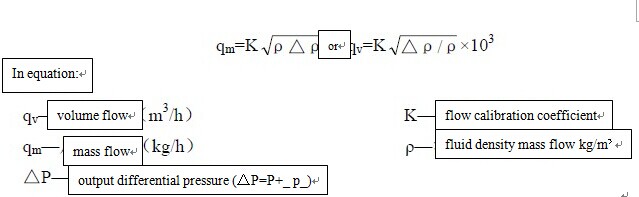

Place a baffle (also known as throttling device) with a flow area smaller than pipeline sectional area in the pipeline which is full of fluid, the fluid in the pipe will form local contraction when it goes through throttling element. Flow area is decreased in the place of contraction, the flow rate increased, static pressure reduced, it will produce a certain differential pressure in the front and back of the throttling device, Porous Balance Flow Sensor operates based on this principle, it is not only able to generate differential pressure, and because the throttling device of Porous Balance Flow Sensor is also a rectifier, the differential pressure produced is particularly stable, according to the law of conservation of mass and the law of constant energy of hydrodynamics, we can calculate volume flow and mass flow of the fluid, as follows:

Main Technical Parameters

|

Inside Nominal Diameter (mm) |

4~3000 |

|

Accuracy Level |

±0.2%, ±0.5%, ±1.0% |

|

Repeatability |

0.1% |

|

Turndown Ratio |

10: 1 (Or higher) |

|

Medium Operating Temperature |

<600℃ |

|

Medium Operating Pressure |

≤25MPa |

|

Permanent Pressure Loss (Pa) |

≤0.31PV2 (P— medium density kg/m3 V— average velocity m/s) can measure bidirectional flow |

![]()

|

Pipe Diameter (DN) |

Length L (mm) |

Internal Thread in Pressure Tappings (RC) |

|

10 |

250 |

1/4 |

|

20 |

250 |

1/4 |

|

25 |

250 |

1/4 |

|

32 |

250 |

1/4 |

|

40 |

250 |

1/4 |

|

50 |

250 |

1/4 |

|

65 |

320 |

1/2 |

|

80 |

320 |

1/2 |

|

100 |

320 |

1/2 |

|

125 |

350 |

1/2 |

|

150 |

350 |

1/2 |

|

200 |

350 |

1/2 |

|

250 |

380 |

1/2 |

|

300 |

420 |

1/2 |

|

350 |

420 |

1/2 |

|

400 |

260 |

1/2 |

|

450 |

490 |

1/2 |

|

500 |

550 |

1/2 |

|

600 |

600 |

1/2 |

|

Pipe Diameter (DN) |

Length L(mm) |

Internal Thread in Pressure Tappings (RC) |

Reference Weight (kg) |

|

10 |

130 |

1/4 |

≤10 |

|

20 |

130 |

1/4 |

≤10 |

|

25 |

130 |

1/4 |

≤10 |

|

32 |

130 |

1/4 |

≤10 |

|

42 |

130 |

1/4 |

≤10 |

|

50 |

130 |

1/4 |

≤10 |

|

65 |

130 |

1/4 |

≤10 |

|

80 |

130 |

1/2 |

15 |

|

100 |

150 |

1/2 |

16 |

|

125 |

150 |

1/2 |

21 |

|

150 |

150 |

1/2 |

29 |

|

200 |

150 |

1/2 |

33 |

|

250 |

150 |

1/2 |

45 |

|

300 |

150 |

1/2 |

57 |

|

350 |

150 |

1/2 |

69 |

|

400 |

150 |

1/2 |

87 |

|

450 |

150 |

1/2 |

96 |

|

500 |

150 |

1/2 |

111 |

|

600 |

150 |

1/2 |

159 |

|

700 |

250 |

1/2 |

200 |

|

800 |

250 |

1/2 |

220 |

|

900 |

260 |

1/2 |

260 |

|

1000 |

300 |

1/2 |

340 |

|

1200 |

300 |

1/2 |

380 |

|

1400 |

300 |

1/2 |

520 |

|

1600 |

300 |

1/2 |

740 |

|

1800 |

320 |

1/2 |

910 |

|

2000 |

350 |

1/2 |

1130 |

|

Pipe Diameter (DN) |

Length L(mm) |

Internal Thread in Pressure Tappings (RC) |

|

10 |

150 |

1/4 |

|

20 |

1/4 |

|

|

25 |

1/4 |

|

|

32 |

1/4 |

|

|

40 |

1/4 |

|

|

50 |

1/4 |

|

|

65 |

1/4 |

|

|

80 |

1/2 |

|

|

100 |

200 |

1/2 |

|

125 |

1/2 |

|

|

150 |

1/2 |

|

|

200 |

1/2 |

|

|

250 |

1/2 |

|

|

300 |

1/2 |

|

|

350 |

250 |

1/2 |

|

400 |

1/2 |

|

|

450 |

1/2 |

|

|

500 |

1/2 |

|

|

600 |

1/2 |